1.Product Introduction

Kingkangda Fancy Tops Machine is a high-speed 5-color fancy tops machine with full servo and intelligent PLC control. It supports flexible multi-color combinations without base tops, offering high productivity, low noise, and stable performance—an ideal choice to enhance fancy tops quality and efficiency.

2.Product Description

The Kingkangda Fancy Tops Machine is a high-speed 5-color fancy tops machine developed through 18 years of technological accumulation and innovation. It integrates internationally branded servo motors and intelligent PLC control to ensure smooth operation and precise color changes. The machine supports simultaneous feeding of up to five color tops without relying on base tops, enabling broader color combinations and complex fancy designs.

Its double-sided structure significantly boosts productivity. The machine is equipped with automatic broken tops stop systems and roller yarn jam detection to ensure safe and smooth production, minimizing downtime and raw material waste. The user-friendly touchscreen interface allows easy parameter settings and program switching, supporting up to 100 programmable steps to meet diverse customer needs.

Compatible with a wide range of fibers from 38mm to 102mm in length, it satisfies the textile industry’s versatile raw material processing requirements. The robust door-frame structure and low-vibration design ensure long-term stable and efficient operation. Optional dust suction devices help maintain a clean production environment. Kingkangda Fancy Tops Machine is your reliable partner for high-quality and efficient fancy tops production.

3. Technical Features

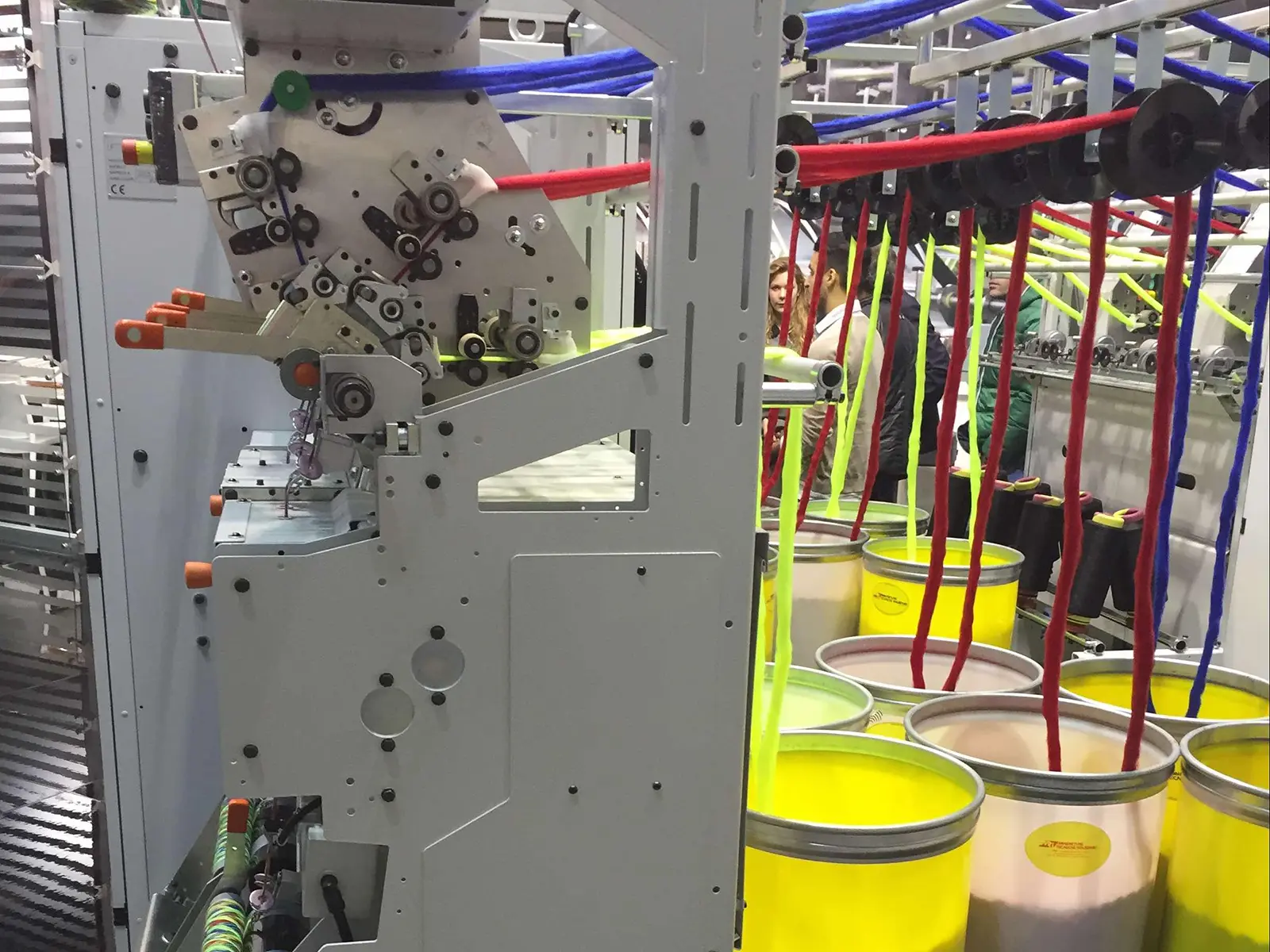

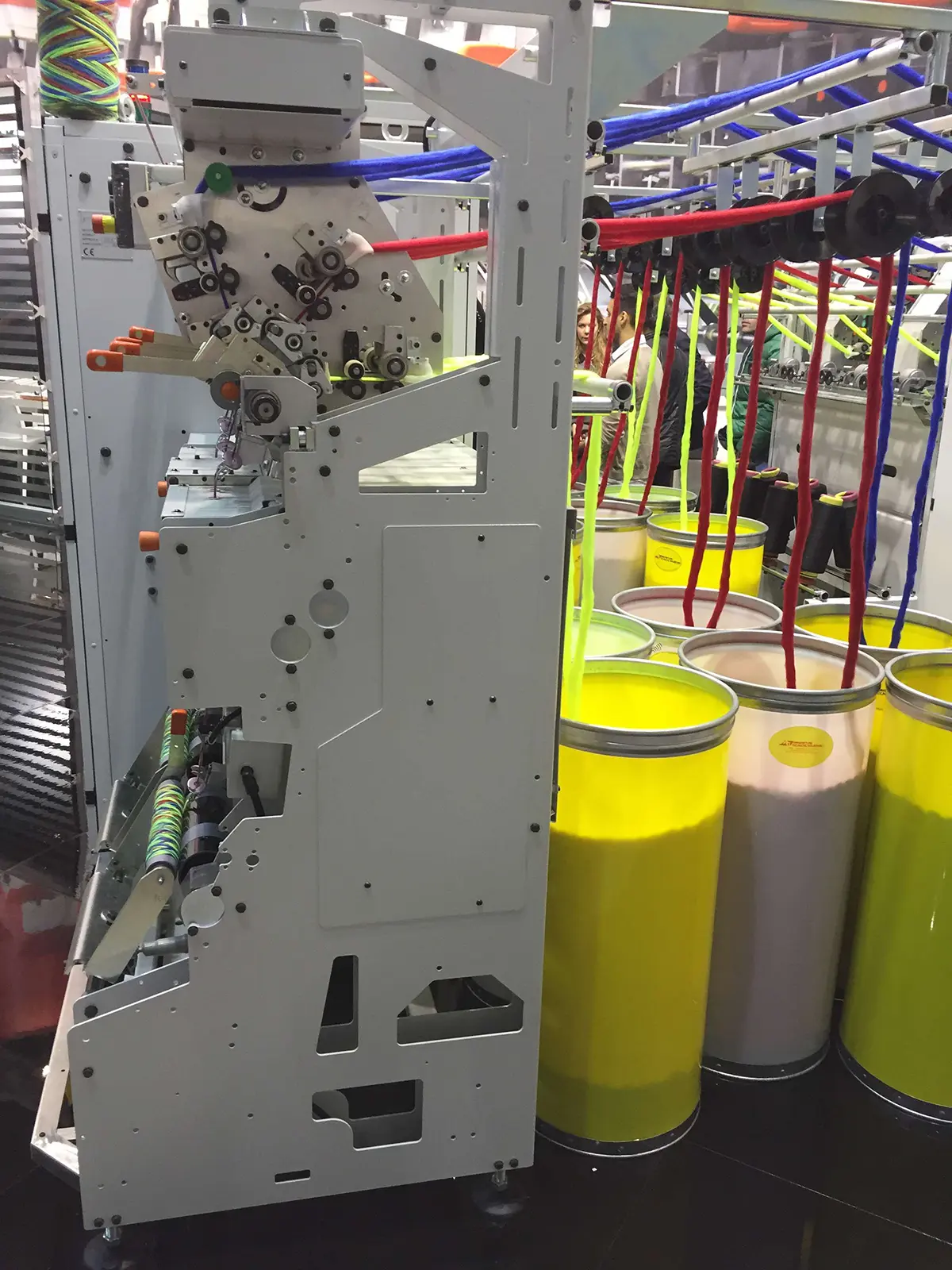

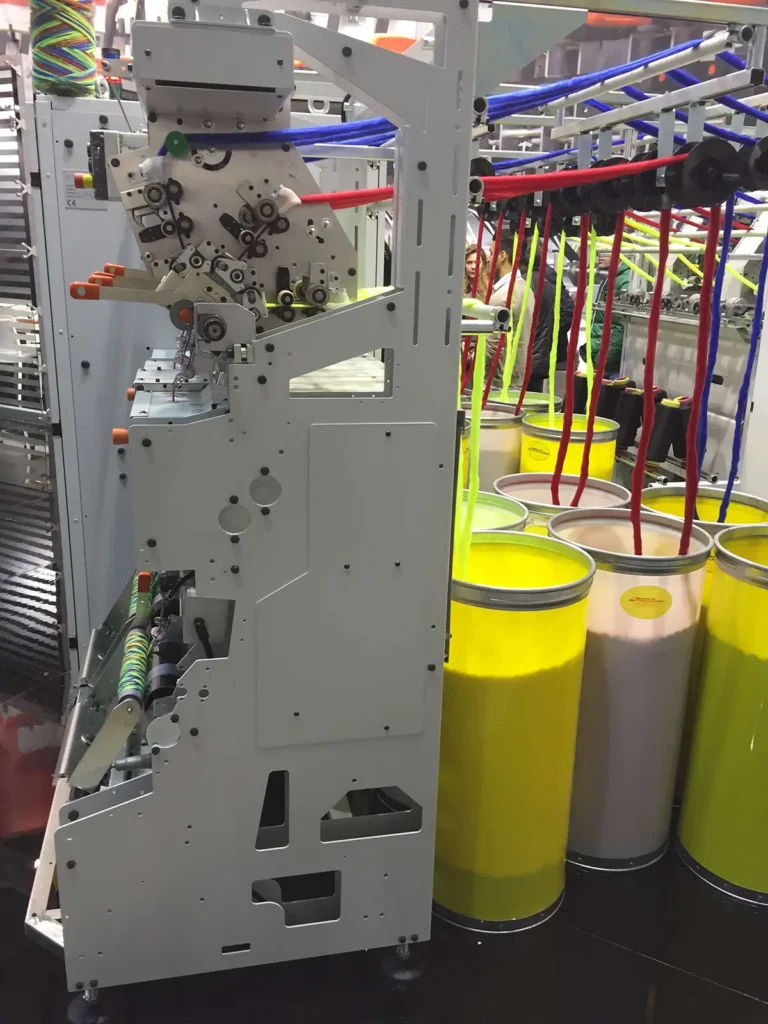

1. Double-Sided Structure for Increased Productivity

The machine adopts a double-sided design that allows simultaneous feeding and processing on both sides, effectively doubling the production capacity without increasing the equipment footprint. This structure optimizes factory space utilization and is ideal for large-scale operations requiring high output, ensuring consistent quality and efficiency in continuous production runs.

2. Full Servo Drive System

Equipped with internationally renowned brand servo motors across all critical transmission points—including color changing, feeding, and output—this system offers precise, rapid response control. The servo-driven mechanism ensures smooth acceleration and deceleration during start-stop processes, eliminating defects such as color blurring or misalignment, thus maintaining excellent color definition and consistent yarn quality.

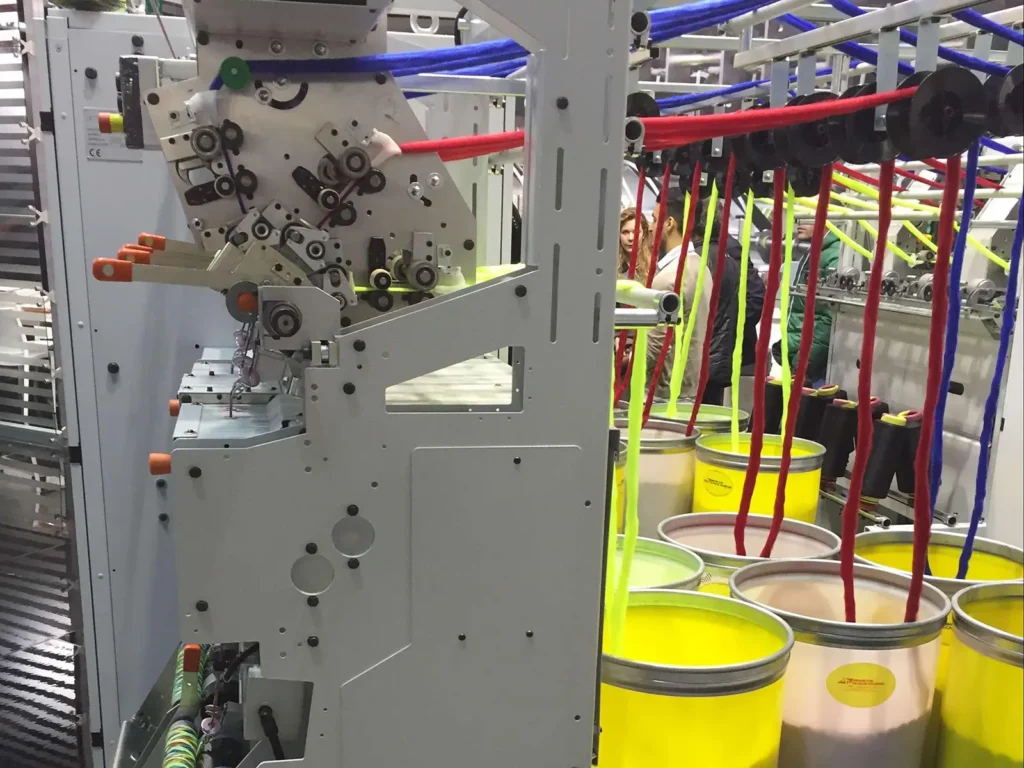

3. Five-Color Fancy Tops Combination

Supports up to five different color tops fed simultaneously, controlled by programmable logic for arbitrary sequence and length changes. This capability enables highly customizable and complex multicolor designs including stripes, gradients, jumps, and other fancy effects. The absence of a base color requirement offers greater creative freedom for diverse product offerings.

4. Base-Color-Free Design

Unlike traditional machines requiring a fixed base color, this machine allows all five colors to be freely combined and switched without relying on a base tops. This design simplifies raw material preparation, reduces costs, and expands the range of color changes, meeting diverse and personalized color top development needs.

5. Intelligent PLC Control with User-Friendly HMI

The machine is equipped with an advanced PLC system integrated with an intuitive touchscreen interface. Operators can easily set and adjust color sequences, segment lengths, and combinations with minimal training. The system supports up to 100 programmable process steps, enabling quick switching between complex patterns and enhancing operational efficiency and consistency.

6. Bidirectional Broken Tops Auto-Stop System

Feeding Side: Each color feeding channel is independently monitored for breaks or tension anomalies. The system triggers alarms or automatic stop immediately upon detection, preventing color sequence errors.

Output Side: Real-time monitoring of tension and optical sensors ensures that issues like yarn jams, breaks, or tangles are detected promptly to stop the machine, protecting product integrity and minimizing waste.

7. Roller Yarn Jam & Wrap Detection Auto-Stop

The rollers are equipped with sensitive jam detection devices that monitor yarn buildup or wrapping issues. Once abnormal yarn tension or blockage is detected, the machine automatically stops to prevent mechanical damage and reduce downtime. This feature enhances machine reliability and protects costly fibers and components.

8. Tops Barrel Cycle Counting Function

The system can be programmed to count the number of output cycles per tops barrel, ensuring consistent product length and pattern repeatability. This feature helps maintain quality control and facilitates downstream processing and inventory management.

9. Wide Fiber Compatibility

The machine accommodates a broad range of fiber types with lengths from 38mm to 102mm, including cotton, acrylic, viscose, polyester, and wool. This flexibility allows manufacturers to process various fibers on the same machine, meeting diverse market demands for fancy yarns.

10. Energy-Efficient and Low-Noise Operation

Optimized mechanical design and transmission reduce vibration and noise levels, creating a comfortable work environment. Energy-saving servo drives and control strategies lower power consumption, helping factories reduce operating costs and meet environmental regulations. Optional dust suction devices maintain cleanliness during production.

4.The main technical parameters

| Parameter | Unit | Specification |

| Installed Power | kW | 5.5 |

| Number of Output Barrels | pcs | 2 |

| Maximum Feeding Count | pcs | 6 |

| Maximum Production Speed | m/min | 30 |

| Broken Tops Auto-Stop Device | Set | 14 |

| Applicable Fiber Length | mm | 38 – 102 |

| Feeding Tops Weight Range | g/m | 4 – 7 |

| Feeding Tops Drafting Range | times | 1.0 – 20 |

| Number of Servo Motors | pcs | 8 |

| High-Speed Comb Box Model | – | OKK Type |

| Max Program Steps | steps | 100 |

| Machine Weight | kg | 1800 |

| Dimensions (L×W×H) | mm | 4280 × 1100 × 1900 |

| Dust Suction Device | Optional |