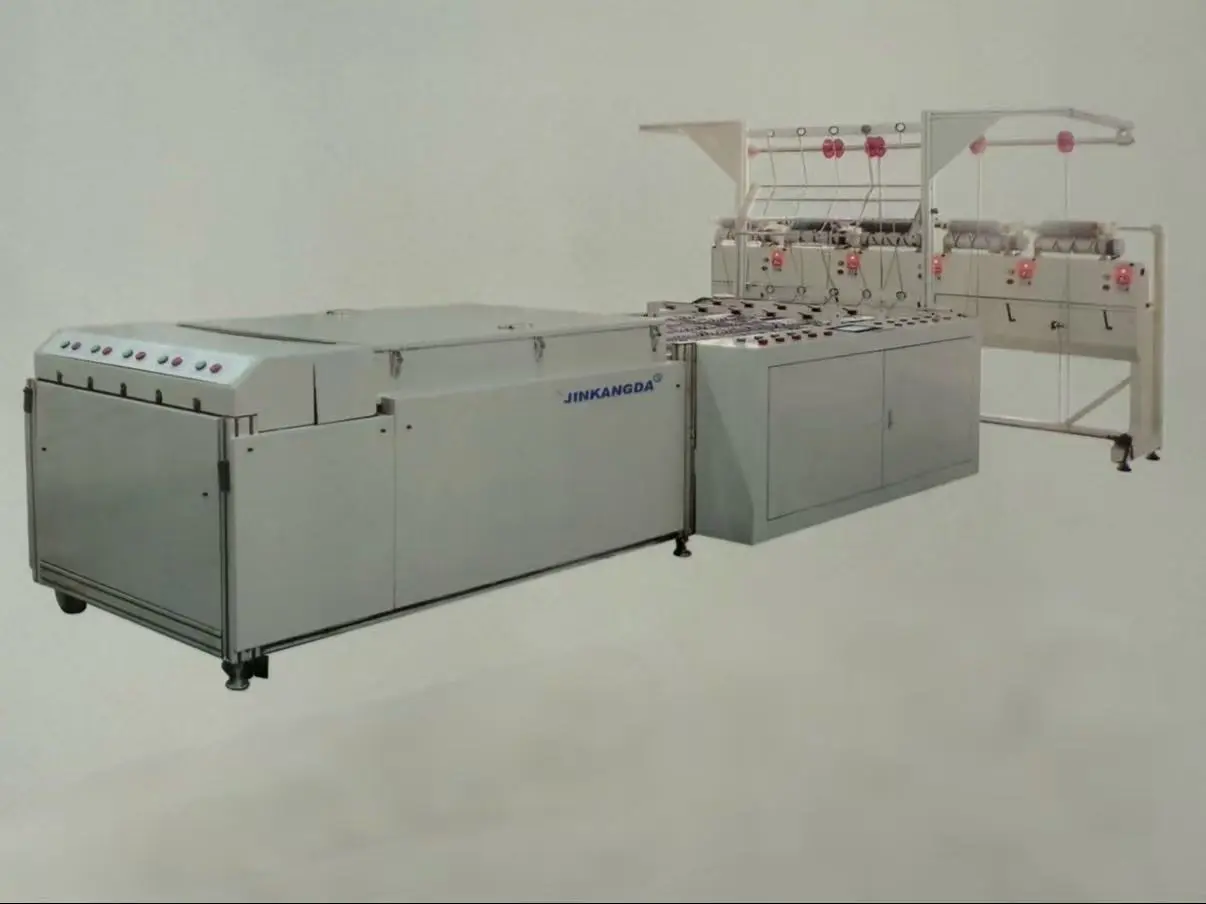

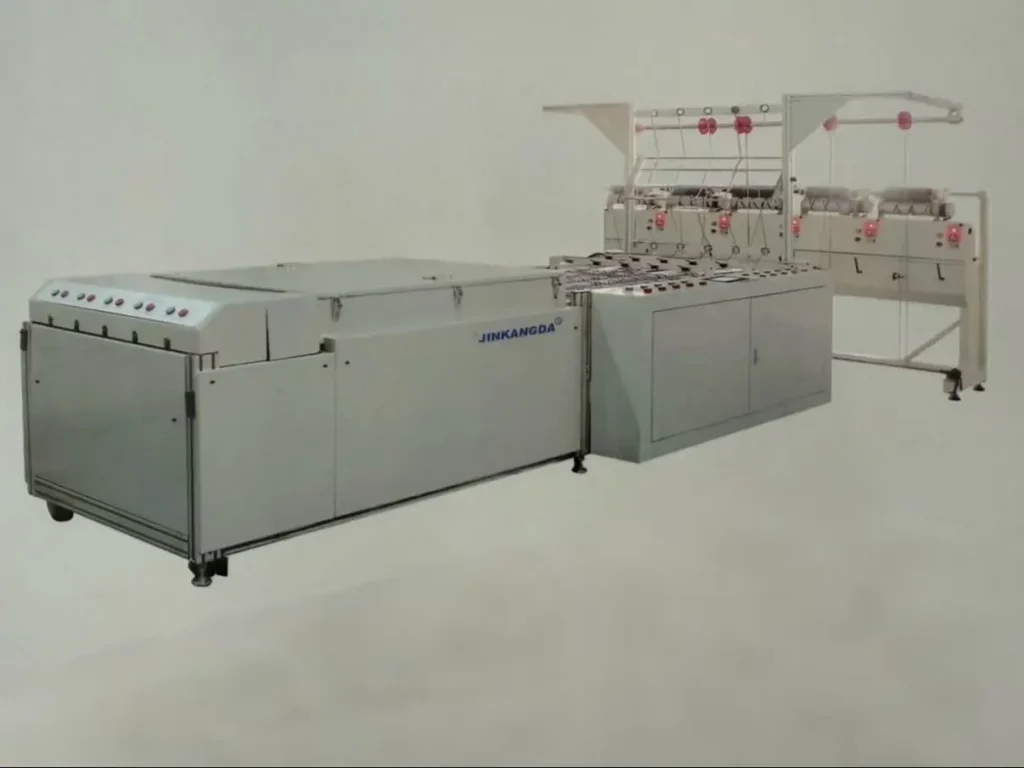

1. Product Introduction

The Continuous Yarn Shrinking and Bulking Machine features independent spindles and an advanced steaming system, designed for continuous processing of a wide range of dyed and hand-knitting yarns. It enhances yarn roundness, softness, and bulk—no need to rewind between cones and hanks.

Looking to simplify finishing and improve yarn quality? This machine offers a seamless and efficient solution.

2.Product Description

This continuous yarn shrinking and bulking machine offers a breakthrough solution for yarn finishing by combining innovative spindle technology with a specialized steaming chamber. Its design eliminates the traditional need to convert yarn from cone to hank or vice versa, greatly simplifying the production workflow. With independent spindles, it ensures uniform treatment of a broad range of dyed and hand-knitting yarns, improving yarn roundness, softness, and overall quality.

The machine integrates automated yarn break detection and stacking, enabling uninterrupted operation and minimizing material waste. The 2-meter cooling zone efficiently stabilizes the yarn after steaming, ensuring dimensional stability and consistent texture. Users can customize the winding output by choosing from automatic cone winders, high-capacity winders, or cake winders to fit different downstream processing or packaging needs.

Engineered for high productivity with energy-efficient components and compact design, this machine is ideal for manufacturers seeking to boost yarn quality and operational efficiency while maintaining flexibility for diverse yarn types and counts. Its user-friendly PLC control system offers real-time monitoring and easy recipe management, helping operators maintain consistent results and reduce downtime.

3. Technical Features

Independent Spindle Drive System

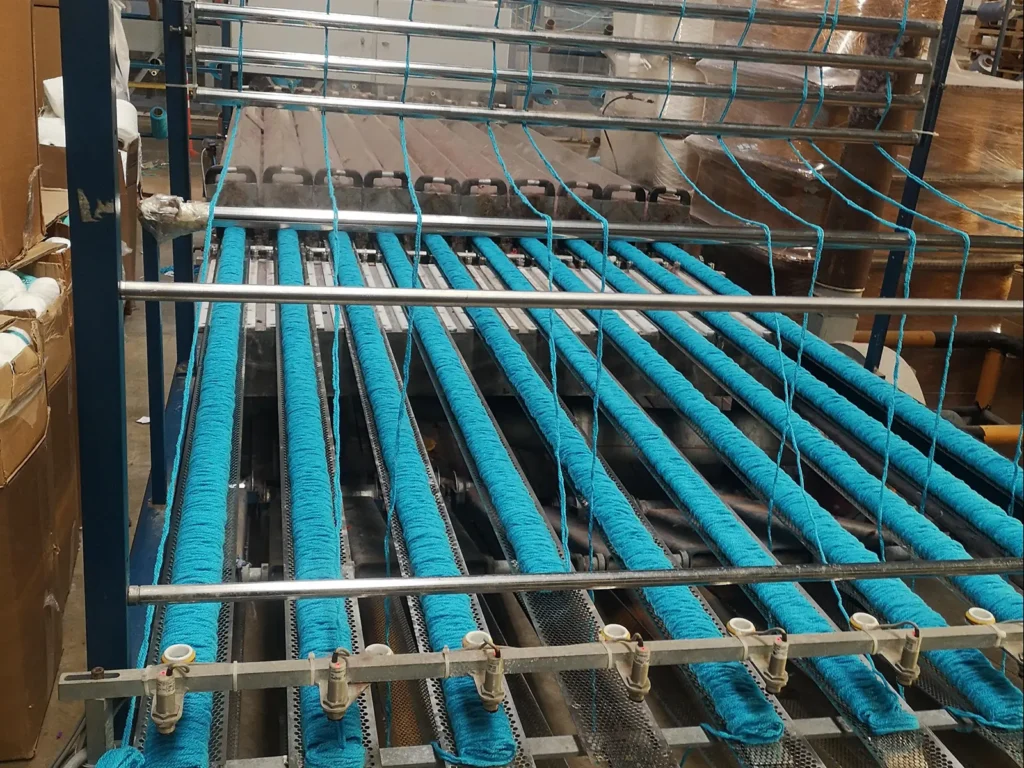

Each spindle is driven by an individual motor with separate control, enabling precise customization of process parameters such as yarn feeding speed, bulking duration, and cooling rate. This independence ensures that each yarn path can be fine-tuned according to its material and target texture, greatly improving yarn uniformity, quality, and bulking effectiveness.

Innovative Dual-Direction Steam Chamber

The machine features a high-efficiency two-way stainless steel insulated steam chamber. Steam is distributed evenly across all yarns, ensuring uniform heat penetration and stable steaming conditions. The dual-direction design eliminates blind zones and supports an impressive shrinkage rate of up to 80%, enhancing yarn bulk, softness, and resilience. Its insulation minimizes thermal loss, reducing energy consumption and improving process stability.

Fully Integrated Continuous Workflow

The system seamlessly integrates creel feeding, automatic yarn break detection, independent yarn stacking units, thermal bulking section, 2-meter cooling zone, and automatic pickup area—all designed for uninterrupted continuous operation. This integration reduces manual handling, minimizes yarn damage, and boosts production efficiency in high-volume environments.

Flexible Output Configuration

Depending on the customer’s needs, the machine can be paired with an automatic cone winder, large-capacity winder, or cake winder. This flexibility allows users to adapt output packaging formats for different applications—whether it’s direct-to-market yarn, dyeing-ready cakes, or bulk-packed cones—maximizing post-processing convenience.

Wide Yarn Compatibility and Count Range

The machine supports a wide yarn count range from 0.5 NM to 15 NM, making it ideal for dyed yarns, hand-knitting yarns, and specialty yarns. Its advanced process control ensures consistent bulking of both fine and coarse yarns, improving fiber roundness, fullness, and overall tactile quality.

Energy-Saving and Compact Design

Engineered for low energy consumption, the machine features optimized heating cycles, insulated chambers, and efficient drive systems. Its compact modular structure saves valuable floor space, making it suitable for both large-scale manufacturers and smaller plants with limited layout flexibility.

Advanced PLC Centralized Control System

The entire production process is managed via a smart PLC system with real-time monitoring, parameter adjustments, and user-friendly touch interface. The control system supports programmable recipe management, fault alarms, production reports, and maintenance reminders—offering full visibility and control over every production detail.

Modular Construction for Easy Maintenance

The machine is built in a modular format with clearly separated zones (feeding, bulking, cooling, pickup, winding). This structure not only simplifies transportation and installation but also makes troubleshooting, part replacement, and future upgrades easier and more cost-effective.

Low Labor Demand and High Automation

Thanks to integrated automation systems—such as auto-stop yarn break sensors, automatic doffing and take-up options—the machine can run with minimal human supervision. This helps reduce operational costs while maintaining stable high-speed output.

4.The main technical parameters

| Parameter | Unit | Specification |

| Yarn Count | NM | 0.5 – 10~15 |

| Cooling Zone Length | mm | 2000 |

| Maximum Shrinkage Rate | % | 80 |

| Spindle Motor Power | kW | 0.5 |

| Steam Chamber Type | – | Two-way Stainless Steel Insulated |

| Yarn Stacking Speed | m/min | 100 – 1000 |

5.Optional Equipment Table

| Equipment Name | Description |

| Saturated Steam Generator | Provides a stable steam source |

| High-Capacity Winder | Suitable for high-output production |

| Cake Winder | Designed for versatile winding requirements |