1.Product Introduction

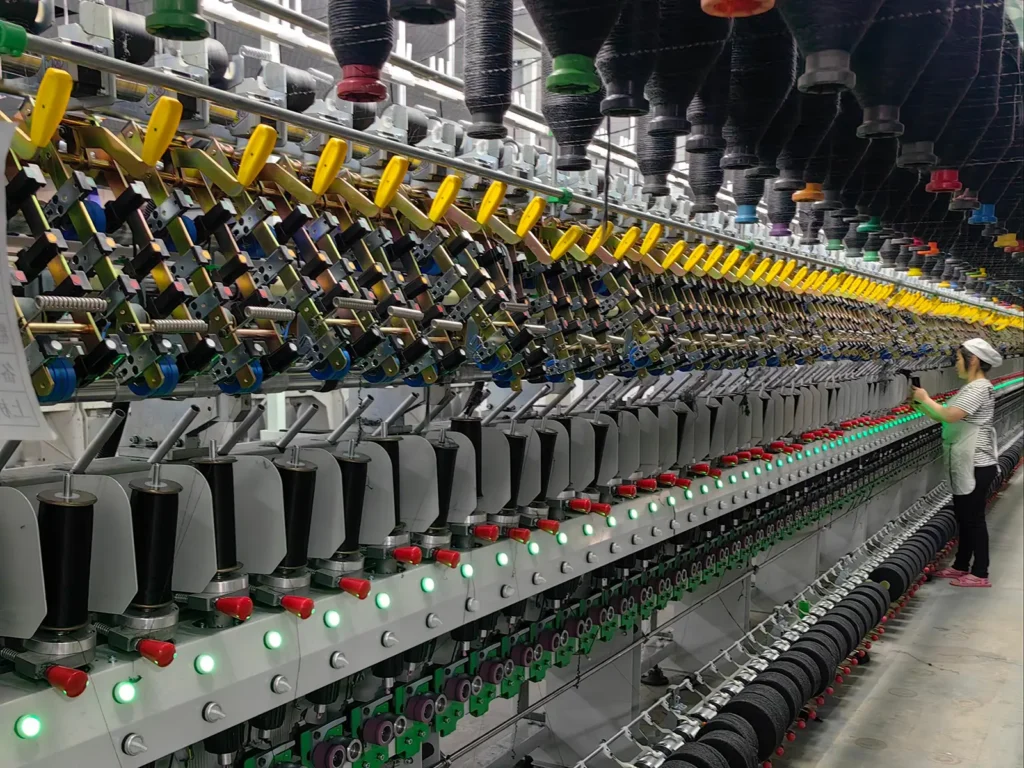

The Kingkangda Two-Roller Double-Hollow Spindle Fancy Twisting Machine is the latest development by Kingkangda, designed for high-quality and large-scale production of yarn-type fancy yarns. With precise engineering and advanced control systems, it ensures stable, versatile, and reliable fancy yarn production. This machine is ideal for processing various yarn structures and achieving diverse twisting effects, meeting the needs of modern textile manufacturers.

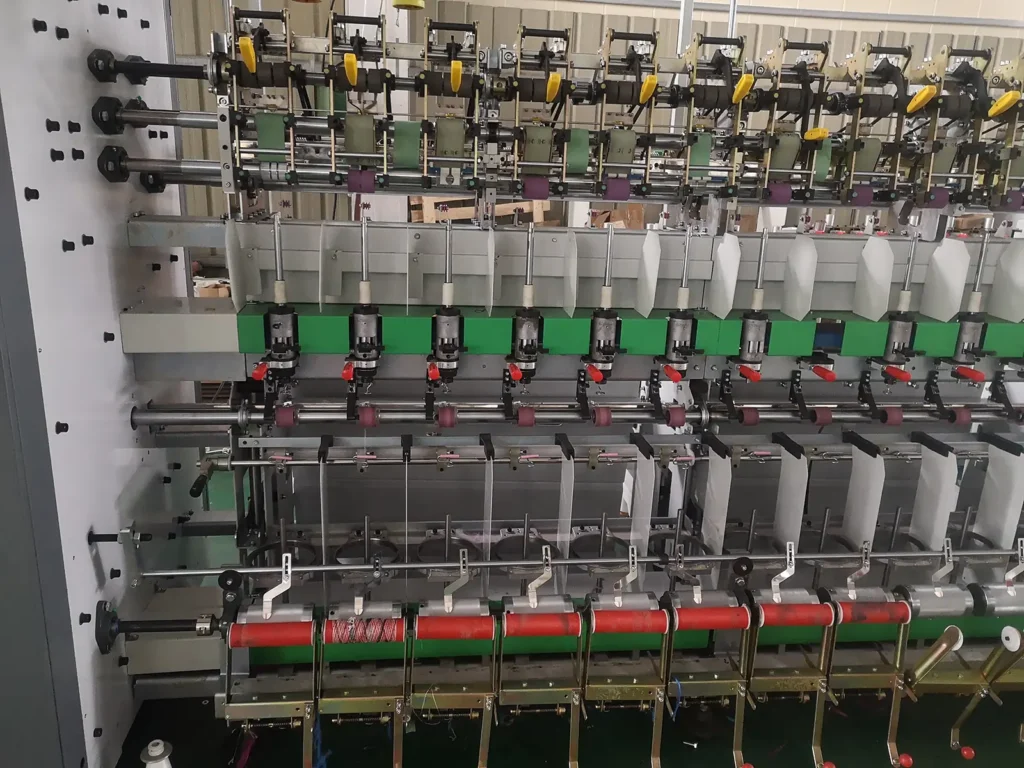

2.Product Description

This machine focuses on post-processing of yarns and features a two-roller system with dual hollow spindles. By applying twisting and untwisting operations, it easily produces a variety of yarn structures and styles. The machine is suitable for traditional double-twist yarns as well as loop yarns, knot yarns (including compressed-knot and slitting-knot yarns), bulky yarns, ripple or slub yarns, and composite yarns in multiple colors. The servo-driven motor system uses the latest shared-bus industrial control technology, ensuring energy efficiency and reliability, while the PLC-based full digital communication system provides high-precision control. This combination guarantees industry-leading performance in yarn quality, energy efficiency, and operational accuracy.

3.Technical Features

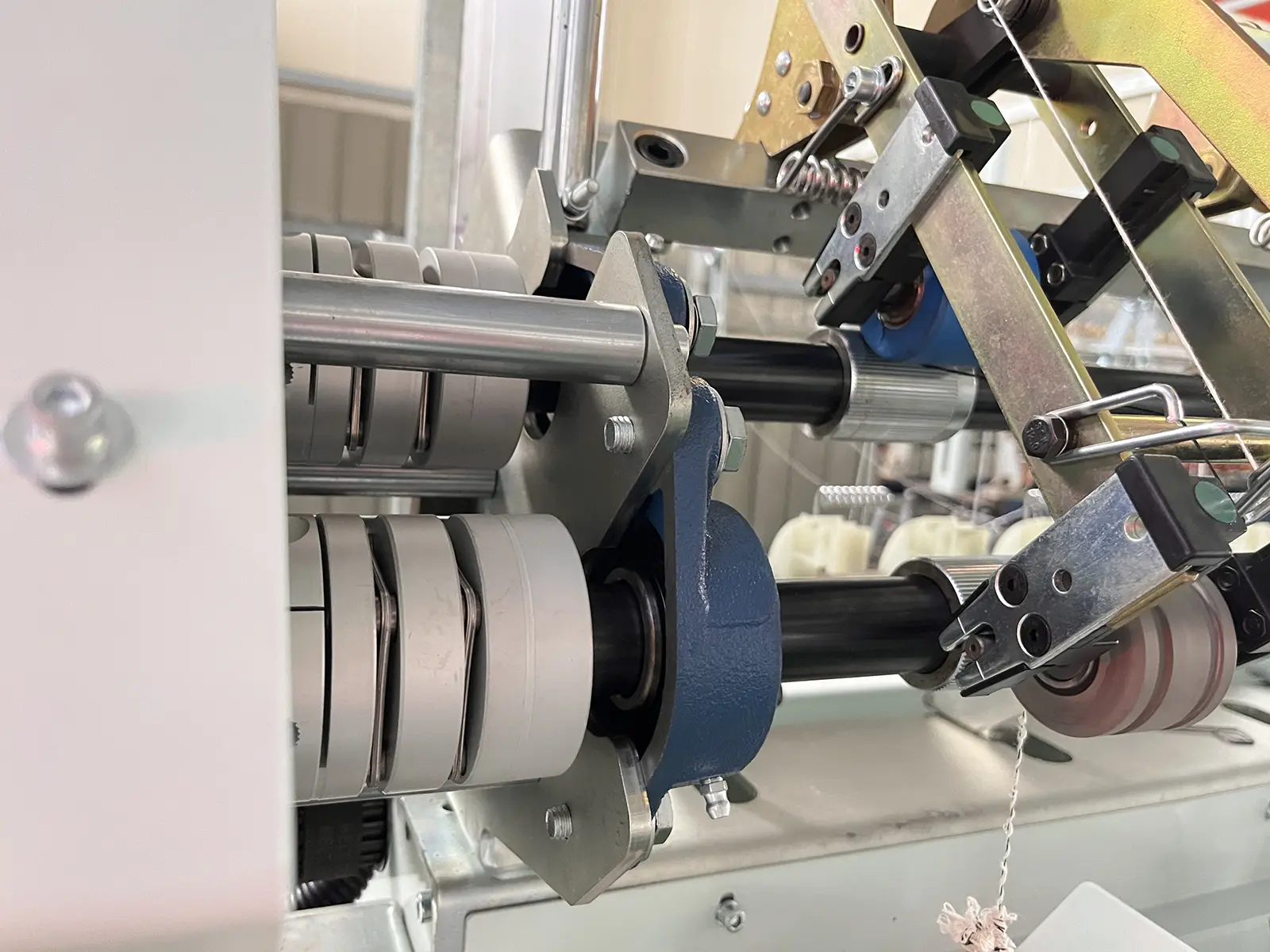

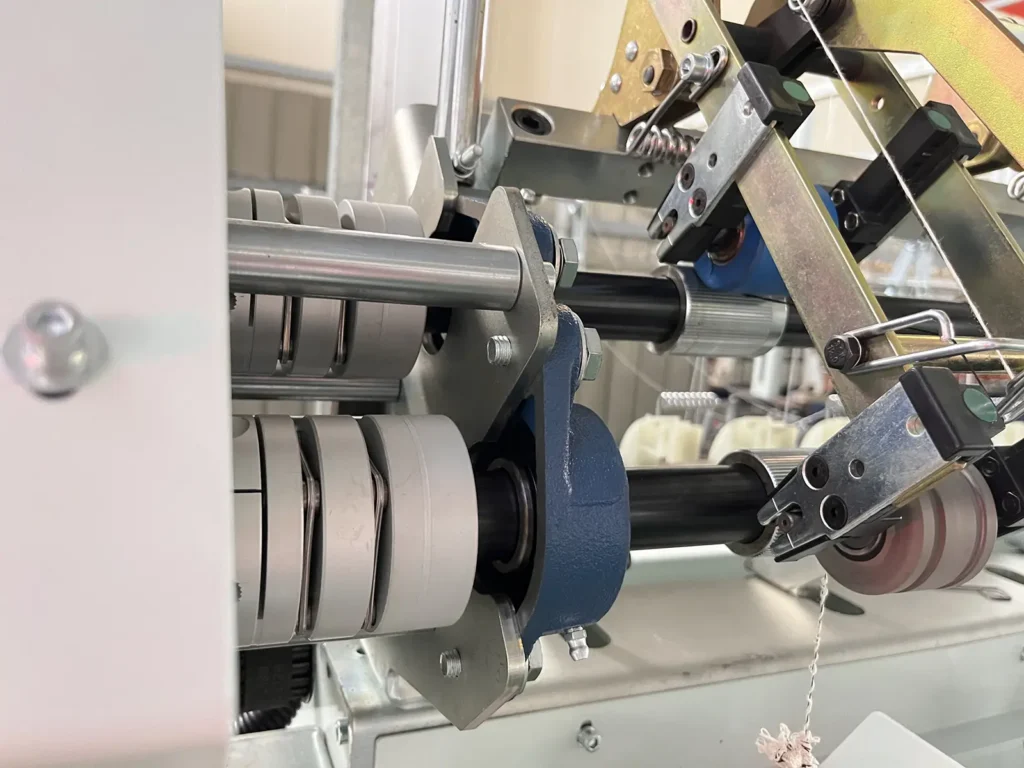

Two-Roller System

Provides stable yarn twisting and untwisting for versatile yarn structures and styles.

Dual Hollow Spindle Design

Enables consistent twist formation and stable yarn quality, suitable for complex yarns.

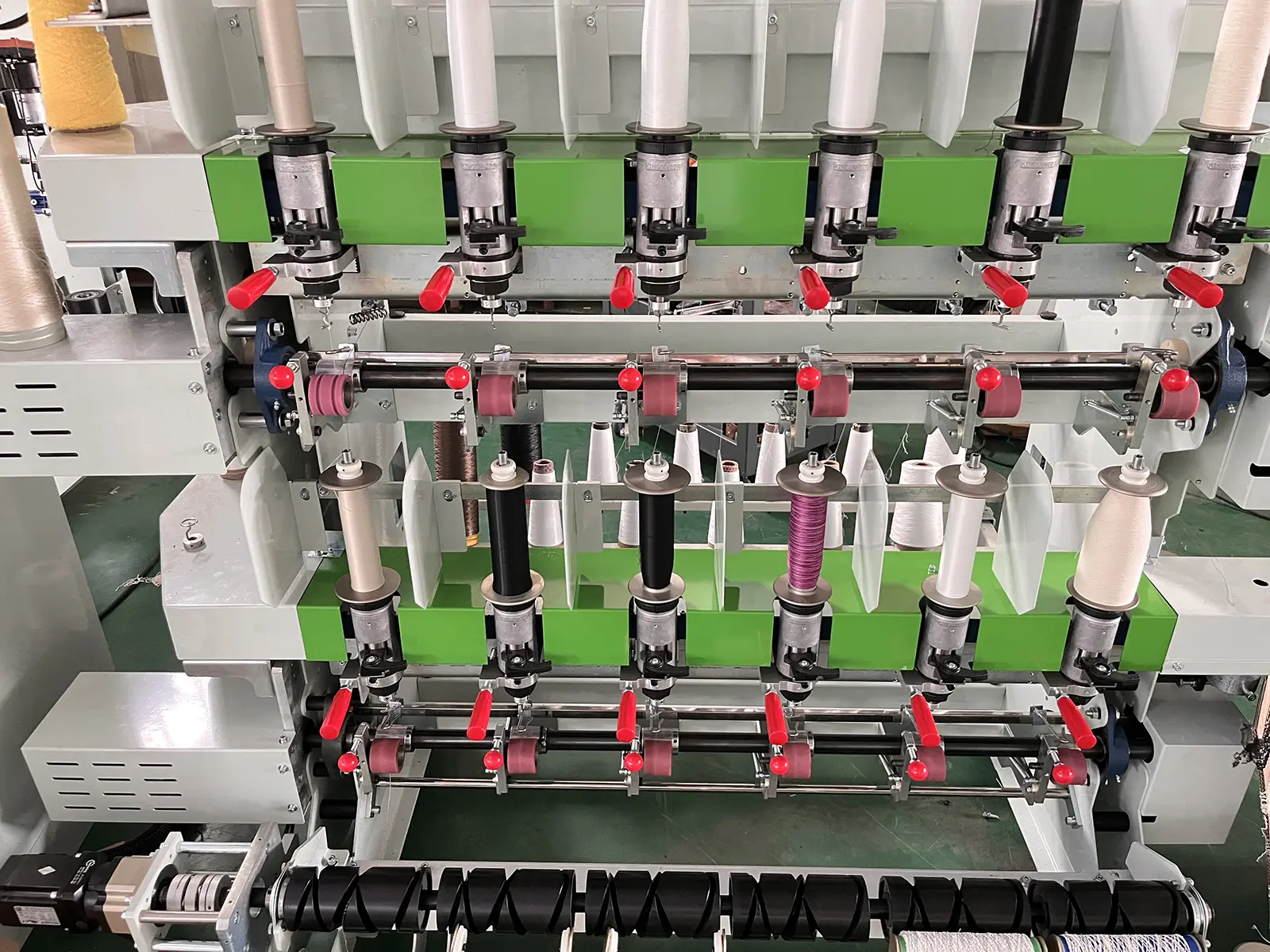

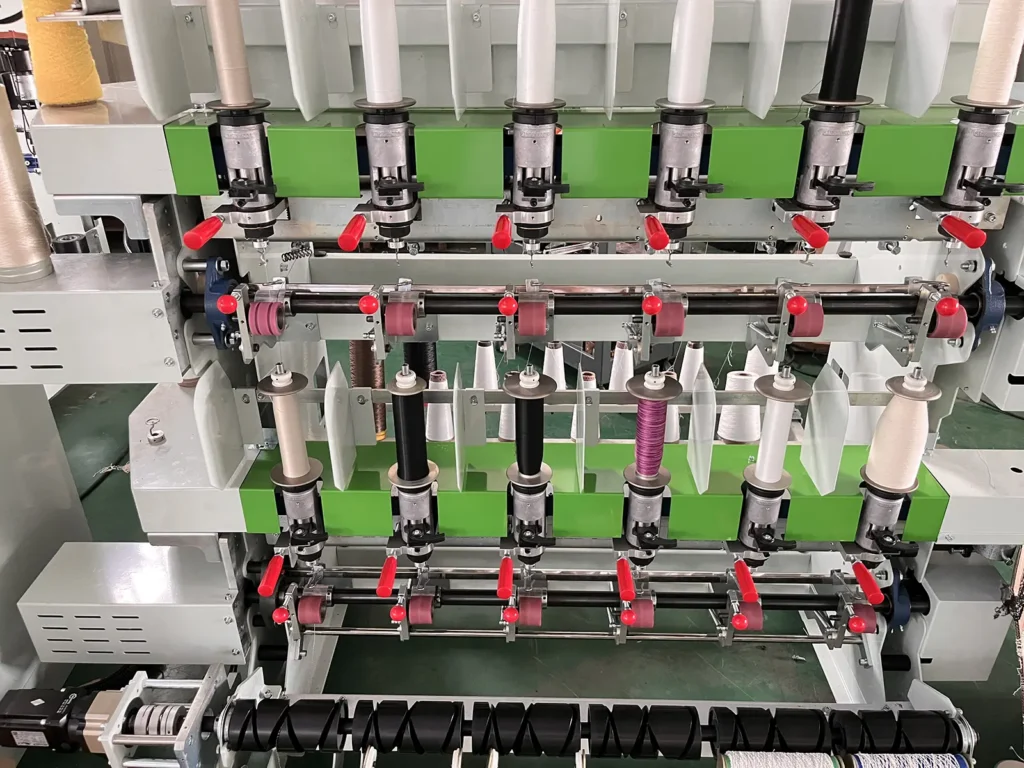

Multi-Color Yarn Feeding

Supports production of multi-colored fancy yarns with uniform structure and reliable quality.

Servo Motor & Shared-Bus Control

Provides precise speed and tension control, energy efficiency, and reliable operation.

PLC Digital Control

Full digital communication ensures high control accuracy and easy recipe storage and switching.

Wide Fancy Yarn Compatibility

Suitable for traditional double-twist, loop, knot, bulky, ripple, slub, and composite yarns in various colors.

| Parameters | Unit | Specification |

| Spindle gauge | mm | 200 |

| Max spindles of single side per section | max | 6 |

| Max spindles of single side | max | 120 |

| Number of sections | max | 20 |

| Upper Hollow spindle speed | rpm | 12000 |

| Lower Hollow spindle speed | rpm | 12000 |

| Basic yarn | / | Dtex20-1000 Nm1-120 |

| Binder yarn | / | Dtex20-1000 Nm16-120 |

| Production speed | Max.m/min | 10-25 |

| power | KW | 10(single sample power) |

| Overall dimension | mm | 3200*1960*2300/section |

| Machinery weight | KG | 500(single machine weight) |