1.Product Introduction

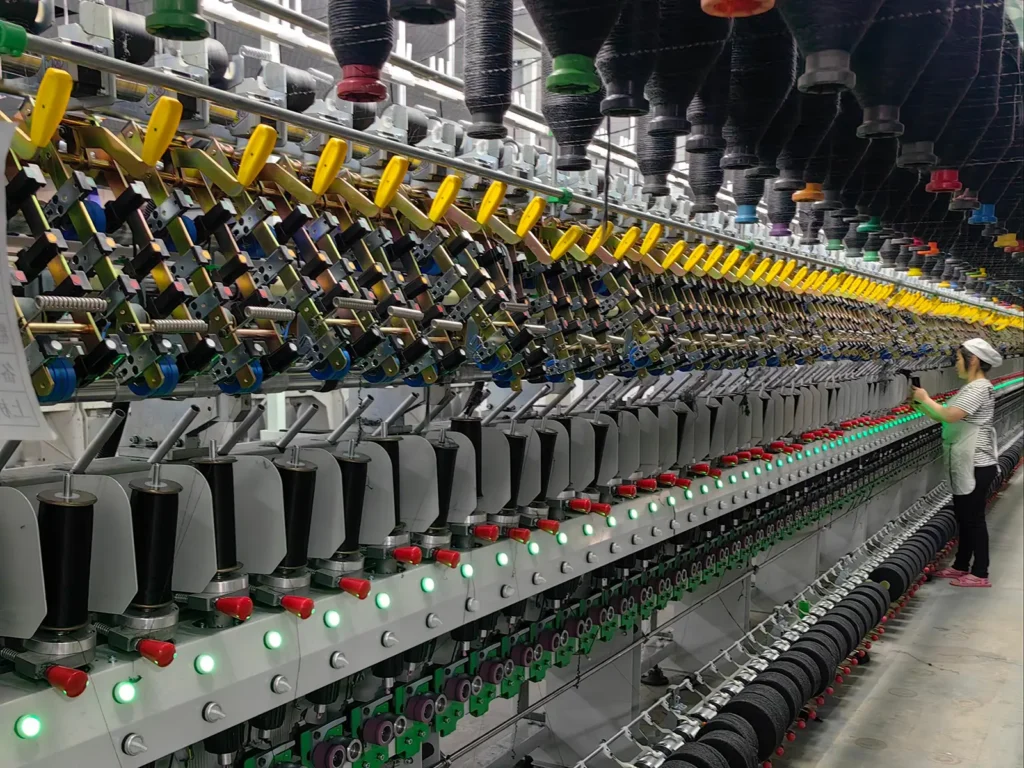

The Kingkangda Yarn Machine is an advanced textile equipment designed to meet the growing demand for efficient, high-quality yarn production. It integrates precise control systems and modern engineering design, ensuring stable performance across different yarn types, including natural fibers, synthetic fibers, and blended materials. The machine is built to optimize yarn properties such as strength, uniformity, and appearance, making it suitable for both fine fashion textiles and robust industrial applications. With its adaptability and reliable operation, it serves as a core solution for modern spinning and yarn processing enterprises.

2.Product Description

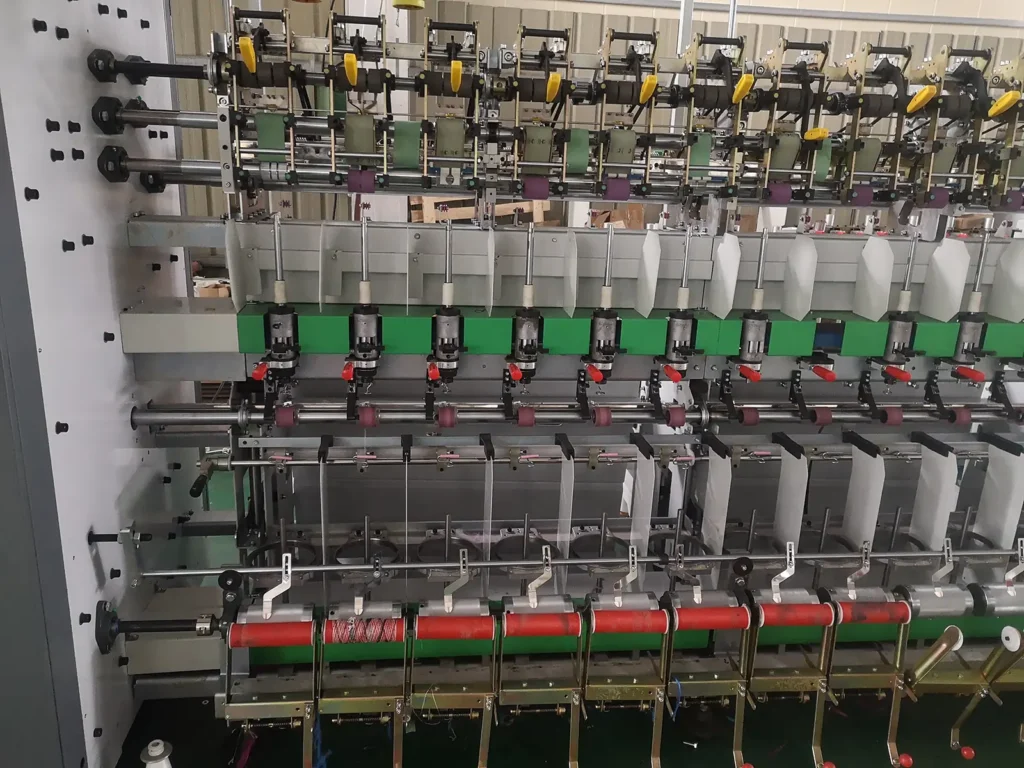

This yarn machine is equipped with an integrated control platform, allowing operators to easily monitor and adjust production parameters. Its design emphasizes user-friendly operation, with functions that ensure consistent yarn quality even under high-speed production conditions. The system supports multiple yarn structures, enabling smooth transitions when processing different materials or specifications.

The modular design makes the machine compact yet highly productive. It can be installed and expanded according to factory requirements, minimizing downtime while maximizing output. With efficient power utilization and automated functions such as tension regulation and process monitoring, the yarn machine not only improves production stability but also reduces labor intensity. Whether producing yarns for apparel, home textiles, or industrial use, it provides manufacturers with a flexible and long-term reliable solution.

3.Technical Features

Versatile Yarn Processing

Handles natural fibers, synthetics, and blends with stable results.

Integrated Control Platform

Centralized operation interface for easy parameter adjustments and real-time monitoring.

Stable High-Speed Operation

Ensures consistent yarn quality even under continuous high-speed production.

Modular and Compact Structure

Flexible installation, expansion, and maintenance with space-saving design.

Energy-Efficient and Automated

Built-in tension control and monitoring systems reduce manual intervention.